Copyright © 2023 Shenzhen Minghui Technology Co., Ltd. All rights reserved Site Map

International Leading Manufacturer of Anti-Mould and Anti-moisture Desiccant

Email:

cocoaduan@sz-minghui.com

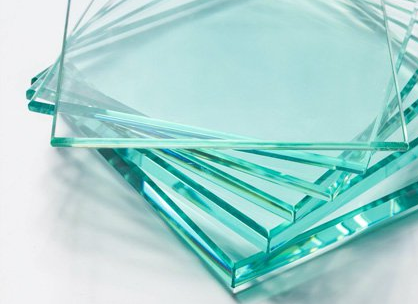

Insulating glass was invented by Americans in 1865. It is a new type of building material with good heat insulation, sound insulation, beautiful appearance, and can reduce the weight of buildings. It is high-efficiency sound insulation and heat insulation glass made by using two (or three) pieces of glass, using a high-strength and high-air tightness composite adhesive to bond the glass pieces to an aluminum alloy frame containing a desiccant.

Insulating glass has relatively strict requirements on desiccants, for example

(1) Ultra-low packaging moisture can ensure that the desiccant has strong water absorption performance.

(2) The super deep adsorption capacity can ensure that the water in the glass interlayer is fully absorbed, avoid condensation, and fully ensure the thermal insulation performance of the insulating glass.

(3) The ultra-low powder falling degree ensures the beautiful light transmission performance of insulating glass.

(4) The ultra-low nitrogen adsorption capacity ensures that the insulating glass is twisted and deformed under different temperature changes, resulting in the glass bursting.

(5) Qualified bulk density ensures that the filling amount of desiccant is controlled within the most economical and reasonable range.

(6) Reasonable acidity and alkalinity to ensure that the insulating glass spacer is not easy to be corroded and salted out.

(7) Higher crushing strength, reducing the crushing during the filling process due to insufficient strength, forming slag, dust, and contaminating the glass.

(8) Low static electricity to ensure that the desiccant is adsorbed on the pipe wall when the machine is filled, blocking the pipe.

Desiccant for insulating glass is divided into two categories: type A desiccant (3A molecular sieve), and type B desiccant (spherical drying material with attapulgite as the main body).

Molecular sieve is a kind of crystalline aluminosilicate mineral pellets, which are connected by silicon-oxygen tetrahedron or aluminum-oxygen tetrahedron through oxygen bridges to form a molecular size (usually 0.3~2 nm) channel and cavity system. Its pore size is comparable to that of general molecules, and only molecules with a diameter smaller than the pore size are allowed to enter. Its pore size can be controlled by different processing techniques. In addition to adsorbing water vapor, it can also adsorb other gases.

According to the proportion and crystal structure of silicon and aluminum, it can be divided into A-type, X-type, Y-type molecular sieves and so on. According to the pore size of molecular sieve, it is divided into 3A molecular sieve, 4A molecular sieve and 5A molecular sieve. Among them, 3A molecular sieve is the most encountered molecular sieve for insulating glass.

Due to its unique crystal structure and mineral composition, attapulgite has the characteristics of high specific surface area, excellent adsorption performance, strong selective adsorption capacity, and large cation exchange capacity. It is a very efficient desiccant. Common attapulgite raw ore often contains a large number of impurities, which will seriously affect the performance of attapulgite. Therefore, it needs to be purified and modified to improve the performance of concave and convex to achieve various purposes.

For more information about the desiccant application for glass, please contact us directly.