Cargo Desiccants, For many years, thousands of containerized cargoes have been damaged by moisture problems. When the containers arrive at the destination, metal is found to be rusty or oxidized, cartons become soft and moldy, bulk coffee, cocoa, beans may be damp, musty, such loss sometimes costs several million dollars. It is caused by two main reasons: Cargo Sweat and Container Rain. Double “breathing area”, which makes adsorption faster, more effective in the same space and period; Reduce relative humidity, Control “dew point”, protect the cargo during the whole ocean voyage.

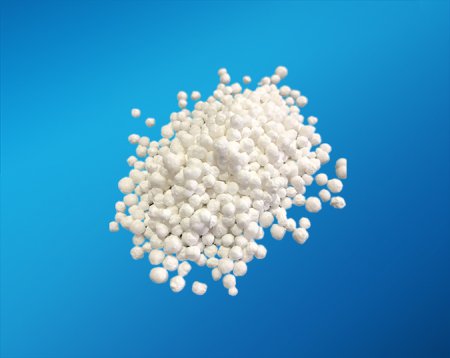

Only 6-laminated non-woven Strips with a hook are inserted into the container grooves, without occupying loading space per 20’GP Container are required. Our -1000g container desiccants create a dry environment in the container. It can effectively absorb humidity, and control “dew point” temperature below the actual temperature, and thus prevent mildew, rust and protect the cargo during the whole ocean voyage. They have a big “breathing area”, which makes adsorption faster, more effective in the same space and period; *It can be inserted into the container grooves, without occupying loading space. Most other CaC12 desiccants, the CaC12 powders inside sachets turns into entire liquid when the adsorption reaches 60%-80%. This state of being liquid lasts several days or even longer (depending on the temperature & humidity conditions), then it slowly turns into gel. It is a high-risk period when the absorbent remains in liquid. When the desiccant sachets are squeezed or pressed during transport or operation, the joint of the sealing part has a risk to be cracked and damaged. As a result, the leakage occurs from the inside liquid, and then the customers’ goods are polluted by the leakage. Our unique formula of absorbents, which is quite different from other desiccant, in physical appearance and in adsorption performance. First, it has a stronger adsorption capacity over 250% in 30 days and will keep absorbing moisture for 60 days. Our saturated adsorption can reach 300%. We can provide a TUY 30 days adsorption test report. This means only 6KG per 20’GP Container is required, unlike most that require 10KG. Second, since most other CaC12 desiccants, the CaC12 powders inside sachets turns into entire liquid when the adsorption reaches 60%-80%. This state of being liquid lasts several days or even longer (depending on the temperature & humidity conditions), then it slowly turns into gel. It is a high-risk period when the absorbent remains in liquid. When the desiccant sachets are squeezed or pressed during transport or operation, the joint of the sealing part has a risk to be cracked and damaged. As a result, the leakage occurs from the inside liquid, and then the customers’ goods are polluted by the leakage. Using our unique formula during the whole process of absorbing moisture, the absorbent remains in solid form, no single minute does it turn into liquid form, from the beginning to the full working conditions, until being saturated. It entirely prevents the risk of liquid leakage.

RELATED PRODUCTS